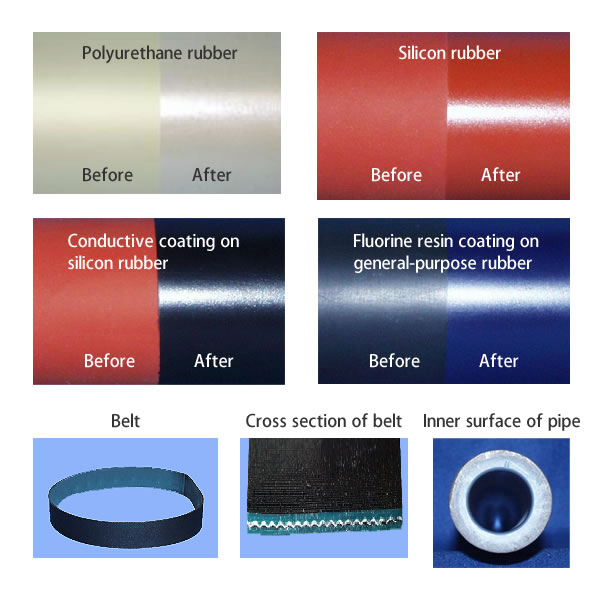

Technical coating for general-purpose products

This is the fluorine resin coating developed for lubricant coating applying to traditional general-purpose products. Coating processing was done to follow stretching fluorine resin on the rubber roll surface by developing special surface finishing primer.

Feature

- Excellent adhesion to rubber, of course, and to metal, plastic, paper and so on. (An exclusive primer is recommended to use for silicon rubber.)

- Low friction and abrasion resistance.

- Oil proof and solvent resistance.

- Binary solvents mixture. Long pot life after mixed, and good for coating operation. Mixed solvents are easy to handle, because it can be diluted in water and can be washed.

Properties of liquid concentrate

- [A liquid]

- [B liquid]

- Solid lubricant: Poly Tetra Fluoro Ethylene resin

- Binder:Heat reactive resin

- Medium:Water

- Appearance of solution:Viscous liquid

- Viscosity:250~300 cps

- Specific gravity:1.0 kg/1

- Flash point:None

- Freezing point:0℃

- Hardening agent

Properties of liquid concentrate

Color tone:Semigloss milky white (or black, blue)

Coefficient of static friction: 0.04~0.05(On a steel plate)

Standard suggested coating thicknes: 10-30 micron

Continuous use temperature: 120℃

Max. use temperature : 150℃

Chemical resistance/solvent resistance: Solvent resistant to inorganic acid. It does not dissolve in oil, gasoline or alcohol. Solvent resistant to ester and ketone.

This is water-based dry film lubricant coating consisting of Emulsion paint (A liquid) containing Poly Tetra Fluoro Ethylene resin (PTFE) and hardening agent (B liquid). This was developed to use for flexible materials, especially for rubber, and forms coating with excellent adhesion.

Remarkable flexibility in a wide range of temperature, especially in cold area, no cracking occurs on the surface and strong coating is maintained.